Aspecte tehnologice privind confecţionarea restaurărilor protetice fixe unidentare din zirconiu (full zirconia) prin metoda CAD/CAM – partea I

Full zirconia single tooth fixed prosthetic restorations obtained through CAD/CAM technology – technological and practical aspects (Part I)

Abstract

The CAD/CAM technology is an innovative alternative in dental prosthodontic that ensures a high quality for all types of prosthetic restorations, with a superior esthetic and functional result. The purpose of this study is to highlight the advantages that emerge from the use of this new technique, regarding precision and accuracy, and also the use of new materials and devices in the manufacture of full zirconia single tooth fixed prosthetic restorations.Keywords

single tooth prosthetic restorationsCAD/CAMfull zirconiaRezumat

Tehnologia CAD/CAM reprezintă o alternativă inovatoare în protetica dentară, care asigură o calitate maximă pentru toate tipurile de tratamente protetice restaurative, cu un rezultat estetic şi funcţional superior. Acest articol are ca obiectiv principal evidenţierea avantajelor pe care le aduce folosirea acestei noi tehnici, prin precizia şi acurateţea realizării pieselor protetice, precum şi prin utilizarea de materiale şi aparate avansate în confecţionarea restaurărilor protetice fixe unidentare din zirconiu (full zirconia).Cuvinte Cheie

restaurări protetice fixe unidentareCAD/CAMfull zirconiaIntroduction

The CAD/CAM technology has developed in Romania, becoming one of the most frequently used technologies in dentistry. This technology represents the future in dental practice (both for clinical component – the dental office, and also for the technological component – dental laboratory). It is an innovative alternative in dental prosthodontics that ensures a high quality for all treatments which involve prosthetic restorations, with a superior esthetic and functional result.

Objective

The purpose of this study is to highlight the advantages that emerge from the use of this new technique, regarding precision and accuracy, and also the use of new materials and devices to manufacture, using full zirconia, single tooth fixed prosthetic restorations(1-4).

Thus, single tooth prosthetic restorations are a long-term therapeutic alternative, their use being recommended according to multiple factors, as follows: the dental team experience (dentist and dental technician), clinical and technical equipment, health status of the patient, and also the financial status and willingness of the patient. Despite the aforementioned factors, fixed single tooth prosthetic restorations offer many advantages for patients who chose this type of treatment regarding functionality, comfort and esthetics(1-4).

General data

Fixed single tooth prosthetic restorations are used to restore morphologically and functionally a single tooth, affected partially or totally by volumetric, coloristic or positioning changes. The CAD/CAM technology is part of the dentistry future and, also, an innovative method.

This type or restorations is obtained following a sequence of clinical and technical stages, that requires a professional cooperation between dentist and dental technician. Clinical stages take place in the dental office, and technical stages take place in the dental laboratory.

The sequence and development of these stages are specific for each prosthetic restoration, depending on their particularities and the material from which they are made of. The success of treatment with single tooth restorations depends both on dentist and dental technician. Considering the fact that single tooth crowns require a high precision of execution, incorporating a variety of technologies, they demand from the dental medical team (dentist and dental technician) a high accuracy of work procedures, order and punctuality in carrying out clinical-technical stages. The choice of therapeutic solutions, such as the use of CAD/CAM technology, must be consistent both with the professional level and the experience of the dental medical team, as well as with the technical-material endowment of the office and dental laboratory(1-4).

Case presentation

The first stage in obtaining single tooth prosthetic restorations is a clinical one. It involves performing the clinical examination, establishing the diagnosis and choosing the treatment plan. Clinical conditions are assessed in order to obtain a good mechanical resistance combined with a pleasant esthetic. The preparation of the prosthetic field is the next clinical stage, and the prosthetic abutment is obtained by milling the tooth to be restored(1-4).

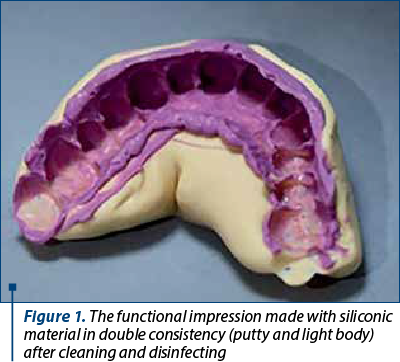

All the impression techniques have in common the highlight by conditioning of cervical area of abutment, which allows a perfect reproduction of this region on the working model. Impression materials have a high precision, with a low viscosity (light body) that allows penetrating the conditioned gingival sulcus(1-4).

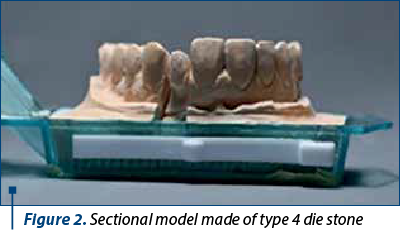

Obtaining the working model is the first technical stage, conducted by the dental technician in the dental laboratory. A sectional model made of high resistance materials is imperative to be used in the technological workflow of full zirconia prosthetic restorations. Using this type of model, the cervical area of abutments is more accessible when removing apart the abutment from the model. Using a dental laboratory scanner, the model is scanned and then transformed in a virtual model using advanced computer software. On the virtual model, the technician creates the design of the virtual pattern of future full zirconia prosthetic restoration. The virtual pattern data is transmitted to milling machine in order to obtain the final product(1-4).

This study is structured on two main parts, based on three clinical cases treated using full zirconia crowns made by CAD/CAM technology. The first part focuses on frontal area, presenting a case where a lateral incisor was restored, and the second part fucuses on the lateral area where a maxillary molar and premolar were restored with full zirconia crowns.

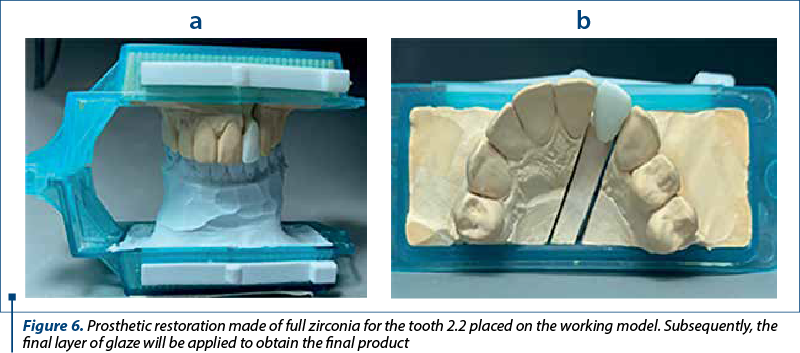

A 37-year-old female patient presented in the dental office for restoring tooth 2.2. The dentist together with the patient decided to create on tooth 2.2 a dental crown made only from zirconia (full zirconia).

An important stage in obtaining a full zirconia crown is dental impression. The recommended materials are condensation silicone in double consistency, putty and light body. The impression of the opposite arch was made using condensation silicon in putty consistency. The relationship between maxillary and mandibular arches was also recorded in this stage, using a putty condensation silicone. The impressions and occlusal registration were cleaned and disinfected, respecting the protocol recommended by the producer of impression material. The working model was cast using a type 4 die stone, and for the opposite arch model, a type 3 die stone was used for casting. The maxillary and mandibular models were mounted in an occlusal simulator, using the occlusal registration.

Using functional impression, the sectional model was cast with type 4 die cast stone, in an Accu-Trac platform.

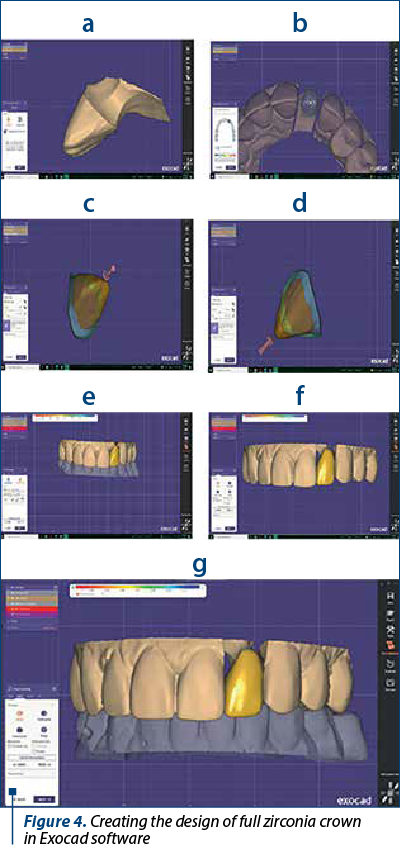

The sectional model and the opposite arch model were scanned using Medit T500, a dental laboratory scanner. The data obtained were transformed using a special computer in virtual dental models.

The next stage was a technical one, using the Exocad software the dental technician made the digital design of the full zirconia crown.

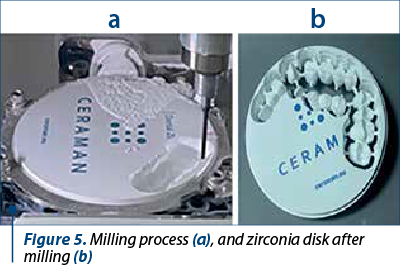

When the design of the crown is ready, the virtual pattern is positioned on the virtual image of zirconia disk, being prepared for the milling process. Electronic data are sent from the computer to the milling machine, in this case a Roland DWX 52DCi dental milling machine.

After the milling process was over, the zirconia disk was removed from the milling machine, and the positioning rods that sustain the zirconia crown framework inside the disk were cut using a laboratory turbine and a diamond bur. Subsequently, the remaining parts of positioning rods from the framework were removed using diamond burs. The obtained framework in this stage was weak and further processing was required for strengthening. The prosthetic restoration was placed on a specific tray filled with ceramic microgrinding beads for the sintering process. The tray was fitted on the oven sintering support, and the specific program for zirconia sintering was started.

After applying the last layer of glaze and completion of restoration, the full zirconia crown was sent to the dental office for internal fit evaluation on natural tooth of the patient.

Discussion

New technologies have the role of improving dental treatments either by obtaining prosthetic parts of a higher quality than the existing ones, or by making the technological process easier for both the doctor and the dental technician.

The emergence of new medical devices, even though they involve additional costs for acquisition and professional training for use, have beneficial effects in the medium and long term, by facilitating medical procedures and reducing material expenses.

CAD/CAM technology in dentistry is not a new technology, instead the equipment has evolved both in terms of scanning devices, milling equipment, but also regarding the materials used to make restorations(5-7).

The scanning equipment, for dental office or dental laboratory, was developed to obtain the best quality of the images, to obtain results similar to or better than the current impression materials(5-8).

Similarly, milling machines allow the realization of much more detailed and precise prosthetic restorations and can be used for a much wider range of materials (PMMA, ceramic, zirconium, metal etc.)(9-13).

In this way, restorations can be made with a high degree of accuracy, in a much shorter time, and with much less materials used. The appearance of zirconia among the materials for prosthetic restorations led to a rethinking of the way in which the prosthetic abutment is obtained. The minimum thickness required for zirconia being smaller than that for ceramic masses, the vital tooth can be preserved even in the abutment stage(14-17).

Conclusions

Definitely, the CAD/CAM technology offers many advantages for the dental laboratory, by automating the manufacturing procedures, with a high quality and a short working time.

The CAD/CAM laboratory systems have developed significantly in recent years, offering a superior and esthetic result compared with a porcelain fused to metal restoration. This technique will develop furthermore and its purposes are precise and helpful in dental medicine, increasing the efficiency of dental treatment, standardizing prosthetic restorations, developing new groups of materials and new concepts of dental treatment.

At the same time, the CAD/CAM technology offers increased resistance to masticatory and wear forces, without the risk of fracture, allowing both a lower thickness of the material, but also the maintenance of the vitality of the polished teeth, by removing a smaller amount of dental tissue after preparation of the prosthetic abutments.

Prosthetic restorations on zirconia infrastructure are lighter than metal-supported prosthetic restorations, and the adaptation to the new prosthetic restoration is faster. n

Acknowledgement: Viorel Ştefan Perieanu is the corresponding author and has equally contributed to this paper with the first author.

Conflicts of interests: The authors declare no conflict of interests.

Bibliografie

-

Bereşescu G. Dinţii umani permanenţi. Press Târgu-Mureş: Ed. University, 2011.

-

Nelson SJ, Ash M.M. Wheeler’s Dental Anatomy, Physiology and Occlusion. 9th Ed., St. Louis: Saunders Elsevier, 2010.

-

Bratu D, Nussbaum R. Bazele clinice şi tehnice ale protezării fixe. 3rd Ed., Bucureşti: Editura Medicală, 2011.

-

Forna N, de Baat C, Bratu D, Mercut V, Petre A, Popşor S, et al. Protetică dentară. 1st ed., Vol. II. Bucharest, Ed. Enciclopedică, 2011.

-

Pan Y, Tam JM, Tsoi JK, Lam WY, Huang R, Chen Z, Pow EH. Evaluation of laboratory scanner accuracy by a novel calibration block for complete-arch implant rehabilitation. J Dent. 2020 Nov; 102: 103476. doi: 10.1016/j.jdent.2020.103476.

-

Anadioti E, Kane B, Zhang Y, Bergler M, Mante F, Blatz MB. Accuracy of Dental and Industrial 3D Printers. J Prosthodont. 2022 Mar; 31(S1): 30-37. doi: 10.1111/jopr.13470.

-

Ueno D, Kobayashi M, Tanaka K, Watanabe T, Nakamura T, Ueda K, Nagano T. Measurement accuracy of alveolar soft tissue contour using a laboratory laser scanner. Odontology. 2018 Apr;106(2): 202-207. doi: 10.1007/s10266-017-0315-4.

-

Ebeid K, Nouh I, Ashraf Y, Cesar PF. Accuracy of different laboratory scanners for scanning of implant-supported full arch fixed prosthesis. J Esthet Restor Dent. 2022 Jul; 34(5):843-848. doi: 10.1111/jerd.12918.

-

Spitznagel FA, Boldt J, Gierthmuehlen PC. CAD/CAM ceramic restorative materials for natural teeth. J Dent Res. 2018 Sep; 97(10): 1082-1091. doi: 10.1177/0022034518779759.

-

Ruse ND, Sadoun MJ. Resin-composite blocks for dental CAD/CAM applications. J Dent Res. 2014 Dec; 93(12): 1232-4. doi: 10.1177/0022034514553976.

-

Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res. 2016 Apr;60(2):72-84. doi: 10.1016/j.jpor.2016.01.003.

-

Prpić V, Schauperl Z, Ćatić A, Dulčić N, Čimić S. Comparison of mechanical properties of 3D-printed, CAD/CAM, and conventional denture base materials.

-

J Prosthodont. 2020 Jul; 29(6): 524-528. doi: 10.1111/jopr.13175.

-

Sulaiman TA. Materials in digital dentistry - A review. J Esthet Restor Dent. 2020 Mar;32(2):171-181. doi: 10.1111/jerd.12566.

-

Schwindling FS, Waldecker M, Rammelsberg P, Rues S, Bömicke W. Tooth substance removal for ceramic single crown materials - an in vitro comparison. Clin Oral Investig. 2019 Aug; 23(8): 3359-3366. doi: 10.1007/s00784-018-2753-y.

-

Baltzer A. All-ceramic single-tooth restorations: Choosing the material to match the preparation – preparing the tooth to match the material. Int J Comput Dent. 2008;11(3-4):241-56.

-

Dal Piva AMO, Tribst JPM, Benalcázar Jalkh EB, Anami LC, Bonfante EA, Bottino MA. Minimal tooth preparation for posterior monolithic ceramic crowns: Effect on the mechanical behavior, reliability and translucency. Dent Mater. 2021 Mar;37(3):e140-e150. doi: 10.1016/j.dental.2020.11.001.

-

Kasem AT, Ellayeh M, Özcan M, Sakrana AA. Three-year clinical evaluation of zirconia and zirconia-reinforced lithium silicate crowns with minimally invasive vertical preparation technique. Clin Oral Investig. 2022 Nov 16. doi: 10.1007/s00784-022-04779-1.