Clasic versus digital în realizarea infrastructurii metalice a restaurărilor protetice fixe (Partea a II-a)

Classic versus digital in the fabrication of the metal infrastructure of fixed prosthetic restoration (Part II)

Abstract

Both the classic method of manufacturing the metal infrastructure of fixed metal-ceramic prosthetic restorations, as well as modern digital technologies such as CAD/CAM offer the patient a stable and resistant prosthetic work with superior esthetics. Due to the high cost of fixed prosthetic restorations made by CAD/CAM technology, they address a smaller number of patients, which is a disadvantage. However, the CAD/CAM method requires a smaller number of production steps than the conventional method, and the errors that may occur along the way are considerably fewer than the errors present during the transformation of the wax pattern into the metal part (by casting).Keywords

metal infrastructureclassicdigitalcastingCAD/CAMRezumat

Atât metoda clasică de confecţionare a instrastructurii metalice a restaurărilor protetice fixe metaloceramice, cât şi tehnologiile digitale moderne de tipul CAD/CAM oferă pacientului o restaurare protetică stabilă, rezistentă şi cu o estetică superioară. Din cauza costului ridicat al restaurărilor protetice fixe realizate prin tehnologia CAD/CAM, acestea se adresează unui număr mai restrâns de pacienţi, ceea ce reprezintă un dezavantaj. Totuşi, metoda CAD/CAM presupune un număr de etape de realizare mai mic decât metoda convenţională, iar erorile ce pot apărea pe parcurs sunt considerabil mai puţine decât erorile prezente pe parcursul transformării machetei în piesa metalică (turnare).Cuvinte Cheie

infrastructură metalicăclasicdigitalturnareCAD/CAMIntroduction

As already mentioned in the first part of this material, dental technology is in a continuous process of innovation and development. Currently, the methods of obtaining prosthetic parts are divided into two categories: classic and modern or digital, even though we are talking about physiognomic components or metal infrastructures(1-4).

The modern methods of obtaining the metal infrastructures for fixed prosthetic restorations are represented by digital technologies, namely laser sintering, hard alloy milling and soft alloy milling (CAD/CAM technology), which involve not only a considerable financial effort on the part of the dental laboratory, the necessary equipment being very expensive, but also a much more serious financial effort for the patients, who will be the beneficiaries of these prosthetic restorations obtained with the help of this revolutionary technology.

Thus, in this second part, two clinical cases of porcelain fused to metal fixed prosthetic restorations are discussed, in which the metal infrastructure is made both by the classical method, used on a large scale with very good results, and by the modern digital method, namely the CAD/CAM technology.

Case presentations

Case 1

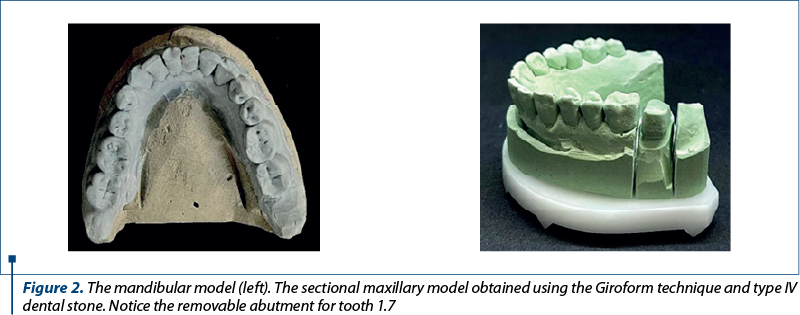

A 35-year-old patient presented to the dental office with carious lesions on tooth 1.7. After a detailed clinical and radiological examination, the dentist together with the patient decided to fabricate a metal-ceramic full coverage crown at the level of the upper second molar 1.7. The metallic infrastructure of this prosthetic restoration was experimentally realized both by the classical method, but also by the modern CAD/CAM digital technology. Up to the stage of casting the working model inclusive, the phases were common. After the moment of obtaining the sectional working model, the stages became totally different.

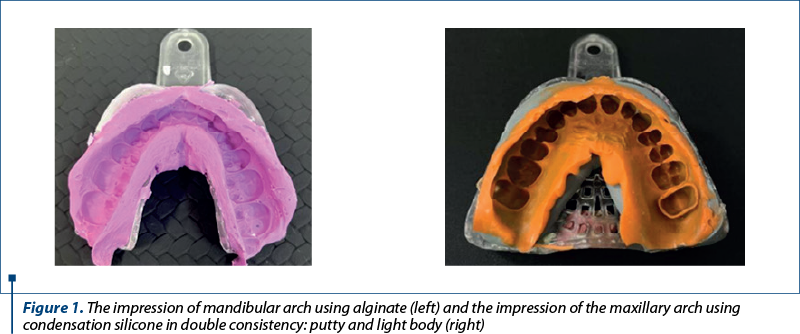

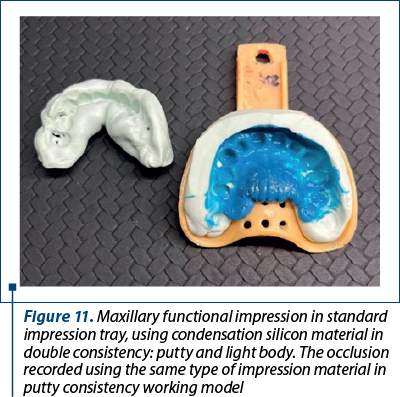

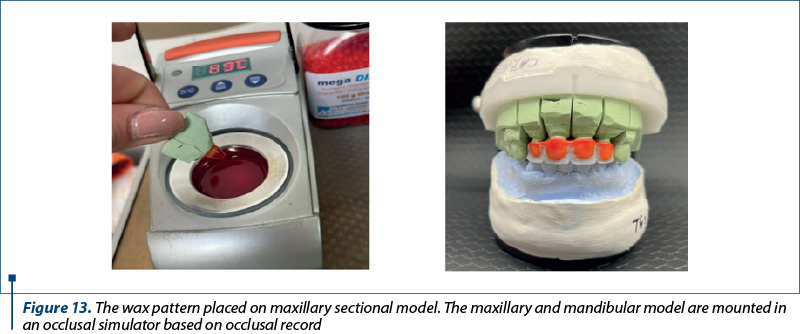

The dental treatment was started with the endodontic treatment and, later, the preparation of the tooth to obtain the prosthetic abutment. Impressions of the arch with the abutment tooth and the antagonistic arch were taken, decontaminated and sent to the dental laboratory. Also, at this stage, the determination and registration of occlusion were carried out by the dentist with the help of a condensing silicone strip of putty consistency.

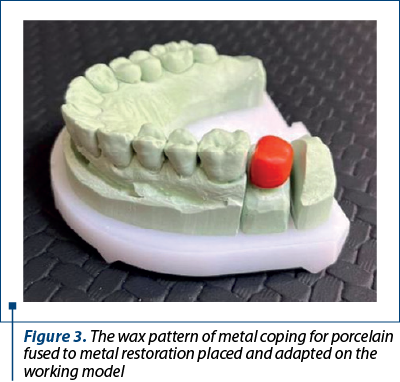

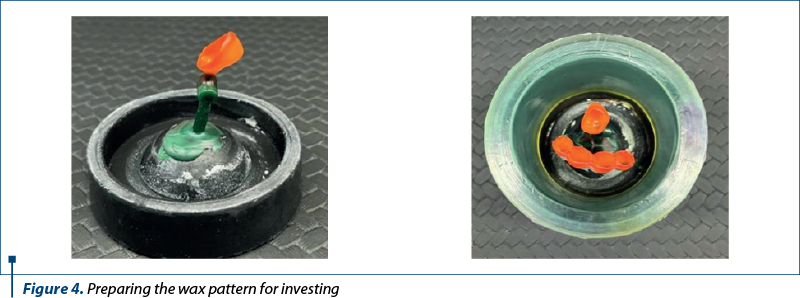

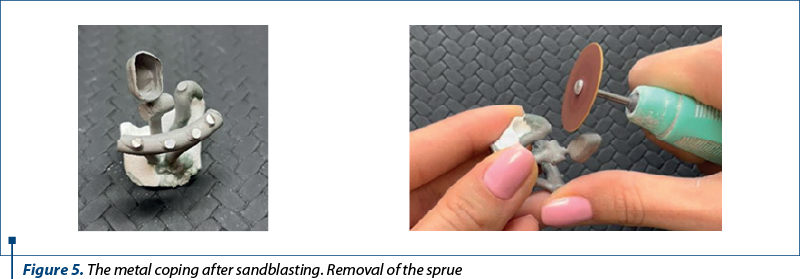

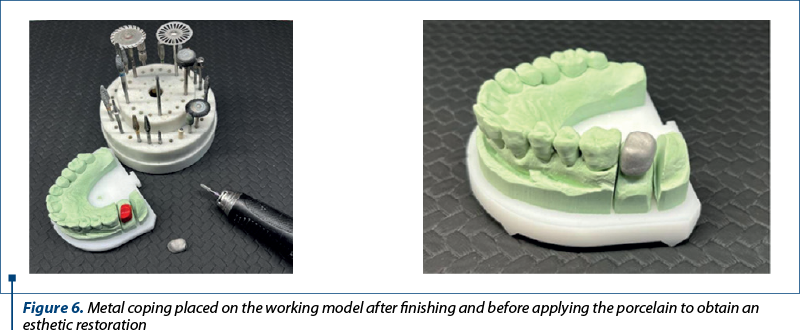

The wax pattern was prepared and invested using a refractory material. By heating, the invested material transformed into a mould, which was filled with cobalt-chrome dental alloy. After casting, the metallic infrastructure was de-vested, sandblasted, the sprue was cut, and the resulting metal infrastructure was then processed.

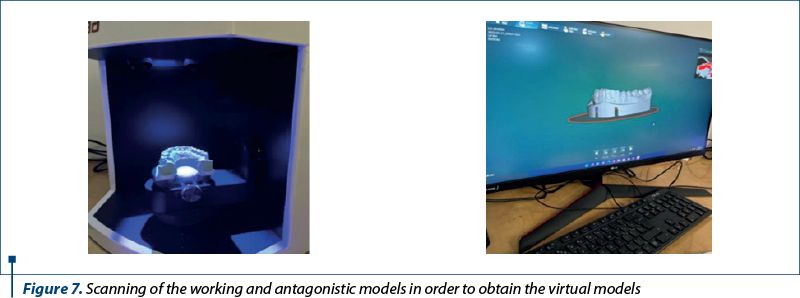

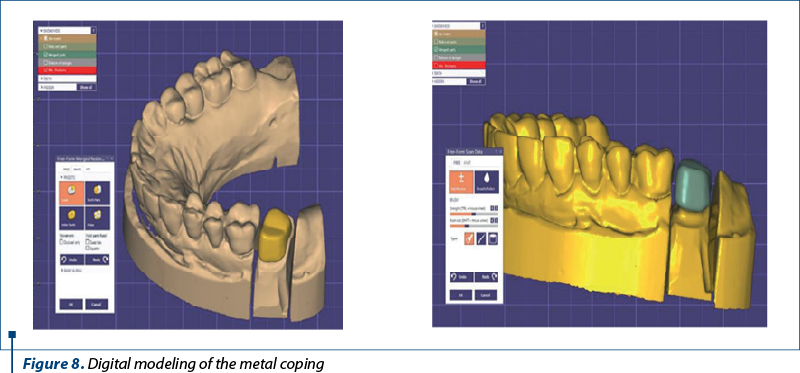

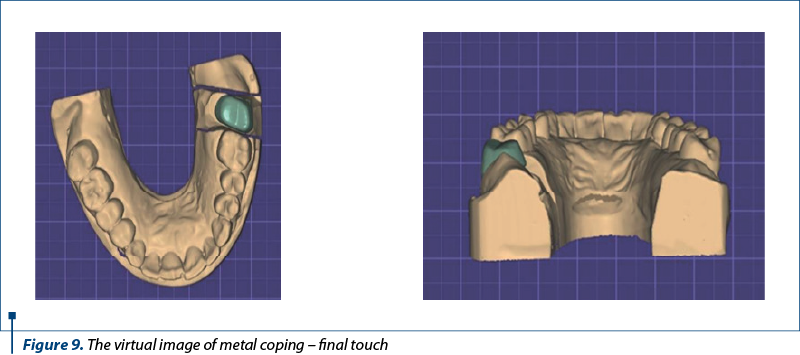

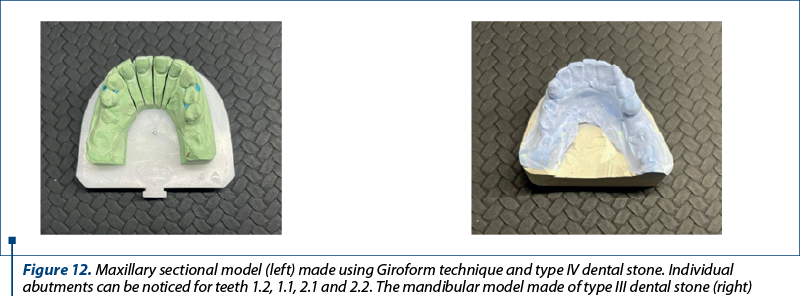

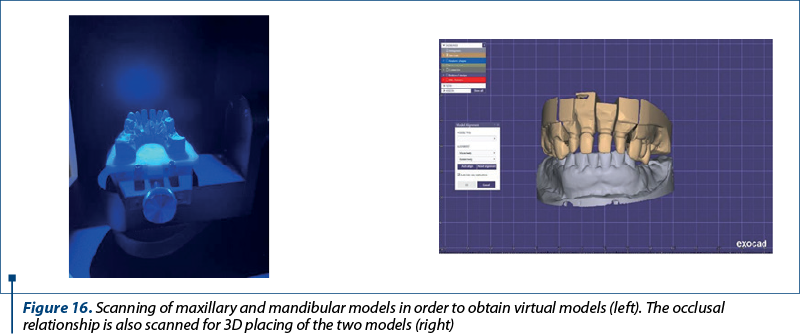

Next, the same clinical case is solved, but the metal infrastructure for 1.7 was obtained by the CAD/CAM method. The maxillary functional model, as well as the mandibular antagonist, previously obtained, were scanned, using a dental technique scanner with automatic calibration and fast processing. For increased accuracy, the abutment on which the prosthetic restoration is made must be scanned individually.

The Exocad program was used to design the metallic infrastructure for tooth 1.7.

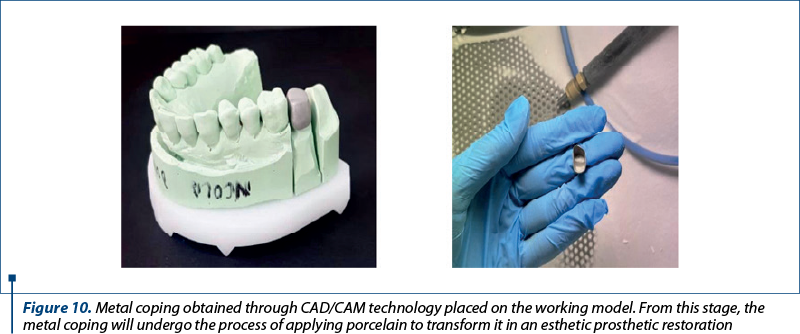

The virtual pattern is sent as a STL file format to the milling center, the metal coping being obtained after a complex milling process (CAM). When the milling process is over, the metal coping requires less finishing comparing the coping or metallic prosthetic restoration obtained using lost wax technique.

Case 2

A 45-year-old patient presented himself in the dental office due to some unpleasant discolorations and extensive carious lesions at the level of frontal upper teeth (1.2, 1.1, 2.1, 2.2). The dentist, in agreement with the patient, decided to fabricate four connected metal-ceramic crowns at the level of the previously mentioned upper frontal teeth: 1.2, 1.1, 2.1 and 2.2. First, the metallic infrastructure will be made using the classic method: the lost wax technique.

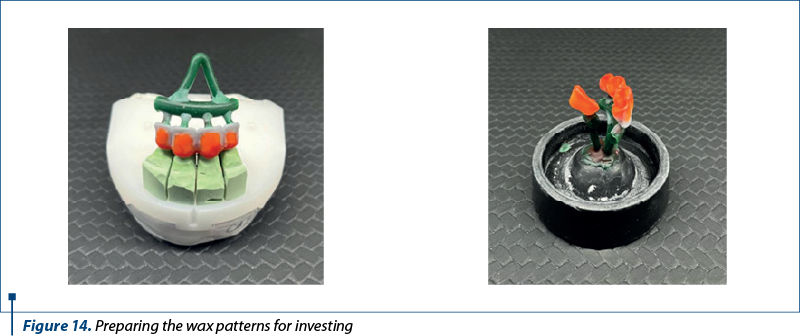

The wax patterns were prepared for investing by applying wax sprues similar to Bego rapid-wax-system. The system is applied on the crucible former and invested using a refractory material.

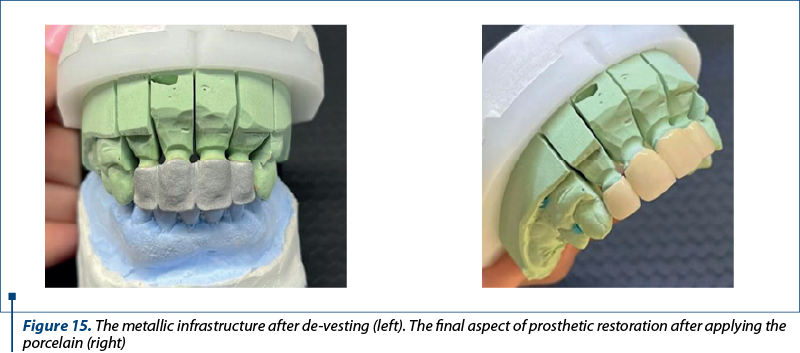

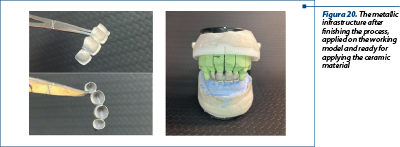

After de-vesting, the metallic infrastructure is processed to remove the excess material that will block the correct insertion on the removable abutments, in order to apply the ceramic material. Subsequently, the ceramic material will be applied on the metallic infrastructure. Next, the same clinical case, but metallic infrastructure for 1.2, 1.1, 2.1 and 2.2 was obtained by CAD/CAM method. Both maxillary and mandibular models were scanned using a laboratory scanner, and removable abutments were scanned individually for a higher accuracy.

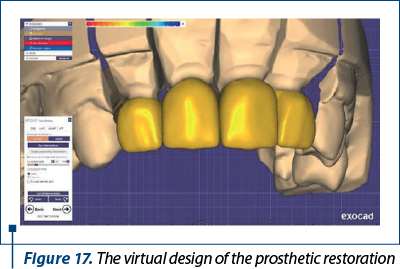

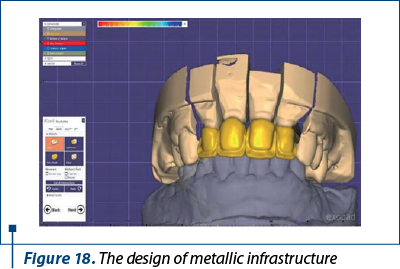

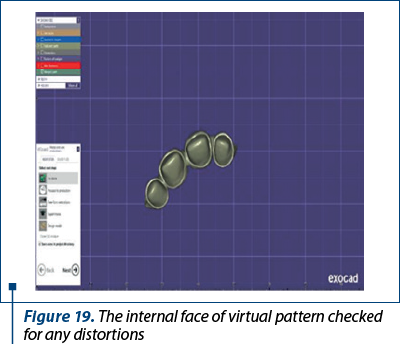

On the virtual maxillary model, using the Exocad program, the virtual pattern of prosthetic restoration was created. The initial design is remodeled to obtain the shape of the metallic infrastructure.

Afterwards, the final shape of the virtual pattern is sent in a STL file format to the milling center. The metal infrastructure being obtained following a complex milling process, it requires less finishing than metal copings obtained through lost wax technique.

Discussion

The first literary references regarding metal-ceramic restorations are made by Perlman in 1949(5,6), who presented restorations with infrastructure based on platinum-based alloys on the surface of which ceramic masses were applied. The subsequent studies were based on the modification of the chemical composition of the ceramic masses so that they could be applied to both noble and base alloys. The shape of the metal infrastructure, as well as the connection between the metal and the ceramic masses were also research subjects.

The emergence of digital processing systems, in addition to facilitating the technological process, favors the obtaining of predictable results, which reduce the risk of errors, especially in restorations made from two materials(7).

In an analysis of the vertical and marginal adaptation of metal copings made using laser sintering, the CAD/CAM procedure and the lost wax technique made by Al-Saleh in 2022 obtained results that are encouraging the development of digital technologies. Thus, the copings made by the CAD/CAM technique present the best adaptation, followed by those made by the lost wax technology(8).

Other studies focused on the creating of the metal copings based on digital information (Mounajjed et al., 2022), and they have come to the conclusion that the modernization of the technological process should not exclude the use of the master cast, because it can be used for small adjustments of the coping, so that the final result is of high quality(9).

Onoral (2020), comparing restorations from three elements – 3-unit Co-Cr metal copings made by selective laser sintering, hard alloy milling, soft alloy milling and casting –, came to the conclusion that the best adaptation is found in restorations made by soft alloy milling(10).

The analysis carried out over time shows that at the beginning of the use of digital technologies for the obtaining of the metal infrastructure for porcelain fused to metal restorations, the accuracy was comparatively low compared to the coping made by the lost wax technique. Thus, research carried out in 2013(11,12) emphasized the qualitative differences of modern technologies in comparison with the lost wax technique, and with the passage of time, more recent studies have shown an increase in the accuracy of restorations made by digital techniques(7-10,13-20). All these indicate that, soon, digital techniques will replace the classic technologies for creating metal infrastructure for metal-ceramic restorations.

Conclusions

Both methods of manufacturing fixed prosthetic restorations offer the patient a stable and resistant prosthetic work, with superior esthetics. Due to the high cost of fixed prosthetic restorations made by CAD/CAM technology, they address a smaller number of patients, which is a disadvantage.

CAD/CAM technology requires a smaller number of production steps than the conventional method, and the errors that may occur along the way are considerably fewer than the errors present during the transformation of the wax pattern into a metal part (casting). Casting defects, unlike milling defects, are much more visible and require more intensive, time-consuming processing.

Designing the virtual pattern of the prosthetic restoration in the Exocad software is much faster and more efficient, unlike special wax modeling techniques.

Although the CAD/CAM technique has two great advantages, such as significantly reduced production time and a high level of productivity, it is a relatively new technique and difficult to access for both dental technicians and patients, due to its high price of the purchase of the components and the system, but also the costs of the finished product.

In conclusion, CAD/CAM is an innovation that will evolve significantly in Romania, thanks to the digital era. This fact does not denote that conventional techniques for obtaining dental prosthetic parts are weaker than modern ones. In dental technology, it is necessary to find solutions to make work easier and to increase productivity. By experimenting with both methods in two different laboratories, a difference in working hours was observed: the working time of the dental technicians in the digital laboratory was estimated at approximately 8 hours per day, in contrast to the classic dental laboratory, where the working hours exceeded long working hours.

Acknowledgement. Viorel Ştefan Perieanu and Bogdan Alexandru Dimitriu are the corresponding authors (Viorel Ştefan Perieanu: viorelperieanu@yahoo.com; Bogdan Alexandru Dimitriu: bogdan.dimitriu@umfcd.ro). Irina-Adriana Beuran and Radu-Cătălin Costea have equally contribution with the first author.

Corresponding authors:

Viorel Ştefan Perieanu

E-mail: viorelperieanu@yahoo.com;

Bogdan Alexandru Dimitriu

E-mail: bogdan.dimitriu@umfcd.ro

Conflict of interest: none declared.

Financial support: none declared.

This work is permanently accessible online free of charge and published under the CC-BY licence.

Bibliografie

- Bereşescu G. Dinţii umani permanenţi. Târgu-Mureş: Ed. University Press, 2011.

- Nelson SJ, Ash MM. Wheeler’s Dental Anatomy, Physiology and Occlusion. 9th Ed. St. Louis: Saunders Elsevier, 2010.

- Bratu D, Nussbaum R. Bazele clinice şi tehnice ale protezării fixe. Ediţia a 3-a. Bucureşti: Ed. Medicală, 2011.

- Forna N, de Baat C, Bratu D, Mercut V, Petre A, Popşor S, et al. Protetică dentară. 1st Ed. Vol. II. Bucureşti: Ed. Enciclopedică, 2011.

- Perlman T. The use of cast platinum and baked porcelain in dental restorations. Dent Dig. 1949;55(6):248-53.

- Perlman T. Further observations on cast platinum and baked porcelain restorations. Dent Dig. 1950;56(7):298-301.

- Kalsekar BG, Gandhi PV, Patil R, Sabane AV, Kadam PP, Bhosale NS. Comparative evaluation of retention and vertical marginal accuracy of Co-Cr copings fabricated using three different techniques: An in vitro study. J Contemp Dent Pract. 2022;23(10): 991-997.

- Al-Saleh S, Vohra F, Albogami SM, Alkhammash NM, Alnashwan MA, Almutairi NS, Aali KA, Alrabiah M, Abduljabbar T. Marginal misfit of 3D-printed (selective laser sintered), CAD-CAM and lost wax technique cobalt chromium copings with shoulder and chamfer finish lines: An in vitro study. Medicina (Kaunas). 2022;58(10):1313.

- Mounajjed R, Taylor T, Hamadah O, Voborná I, Al-Akkad M. Assessment of the readiness of restorations manufactured by CAD/CAM in terms of marginal fit (Part I). Peer J. 2022;10:e13280.

- Onoral O. Marginal discrepancy of 3-unit Co-Cr metal copings fabricated with additive and subtractive manners: A comparative study. Niger J Clin Pract. 2020;23(9):1274-1280.

- Vojdani M, Torabi K, Farjood E, Khaledi A. Comparison the marginal and internal fit of metal copings cast from wax patterns fabricated by CAD/CAM and conventional wax up techniques. J Dent (Shiraz). 2013;14(3):118-29.

- Suleiman SH, Vult von Steyern P. Fracture strength of porcelain fused to metal crowns made of cast, milled or laser-sintered cobalt-chromium. Acta Odontol Scand. 2013;71(5):1280-9.

- Bodnar DC, Dimova C, Bodnar T, Cristache CM, Burlibaşa M, Sfeatcu R. Dental management of patient with psychiatric disorders. Modern Medicine. 2010;17(10):538-543.

- Burlibaşa M, Burlibaşa L, Gavrilă LB, Gavrilă VR, Gavrilă L. microRNA a macro revolution in medical biotechnologies. Roum Biotech Lett. 2008;13(6):3977-3983.

- Bodnar DC, Pantea M, Bodnar T, Burlibaşa M, Dumitru SG, Cristache CM. Patologia mucoasei orale la pacienţii vârstnici – studiu clinico-statistic. Acta Medica Transilvanica. 2012;2(2):56-60.

- Cristache CM, Totu EE, Burlibaşa M, Tănase G, Iorgulescu G, Burlibaşa L. Preliminary study on genotoxicity assessment of an innovative topical treatment for periodontal disease. Revista de Chimie. 2020;71(2):145-150.

- Totu EE, Cristache CM, Perieanu VS, Burlibaşa M, Petre DC, Burlibaşa L. Are nano TiO2 inclusions improving biocompatibility of photocurable polydimethylsiloxane for maxillofacial prothesis manufacturing?. Applied Sciences. 2021;11(9):3777.

- Totu EE, Cristache CM, Isildak I, Yldirim R, Burlibaşa M, Nigde M, Burlibaşa L. Citotoxicity and genotoxicity assessment of the PMMA-TiO2 nanocompozites for stereolithographic complete dentures manufacturing. Revista de Chimie. 2018;69(5):1160-1165.

- Burlibaşa M, Cristache CM, Georgescu SR, Dumitriu AS, Neamţu R. Toxicity of titan and nikel-cobalt-chromium alloys. Metalurgia International. 2009;14:20-22.

- Cristache CM, Burlibaşa M, Tănase G, Niţescu M, Neamţu R. Titanium as dental implant material. Metalurgia International. 2009;14:14-16.